When it comes to what kind of material handling equipment you need for your job, there are many options. Counterbalanced Diesel forklifts and telescopic forklifts are just a few of them.

Here, we will explore the core differences between counterbalanced forklifts and telescopic forklifts and explain how each type of forklift can be used for different jobs. What is the difference between a counterbalanced forklift and a telescopic forklift? Which one is best for your job needs?

Counterbalanced Diesel forklifts

The term “counterbalanced forklift” comes from the design of forklifts that are equipped with heavy counterweights to offset the weight of the load carried by the forklift’s front tires.

Internal combustion forklifts have a counterweight integrated into the rear of the forklift to balance the load.

Advantages of counterbalanced forklifts

Lifting a variety of weights

Counterbalanced forklifts are the most common type of forklift and are designed and built to safely lift a variety of weights, from 1 ton to 10 tons.

The greater the lifting capacity of a forklift, the larger its size will be, as the built-in counterweight must be large enough to offset the weight of the load picked up by the forklift to prevent the forklift from tipping over.

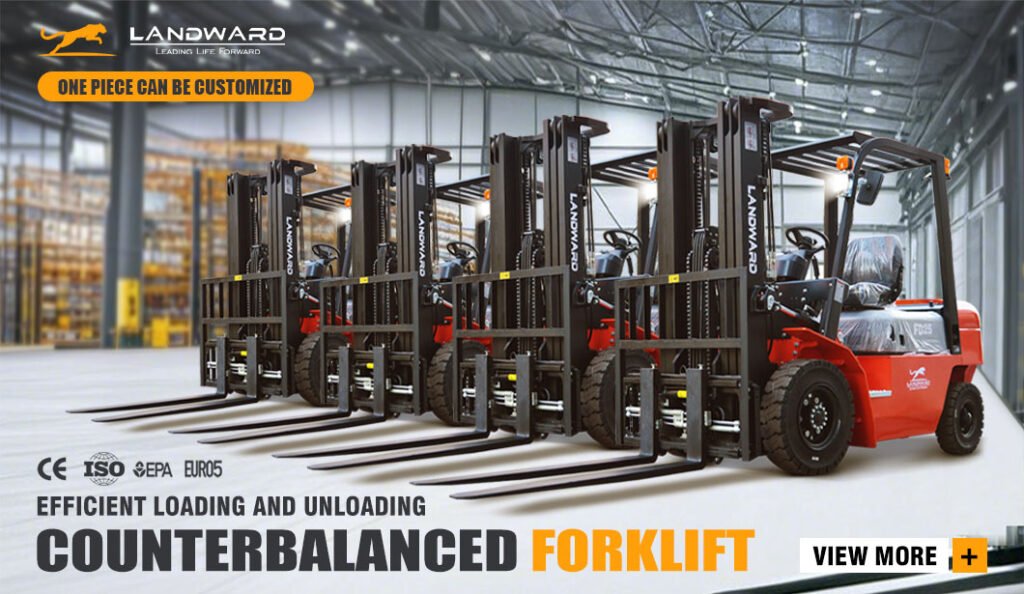

Counterbalanced forklifts

Different fuel types

Another advantage of counterbalanced forklifts is that they can be used on a variety of fuels.

Fuel types include:

Different fuel types allow forklifts to be tailored to specific applications, for example diesel-powered counterbalanced forklifts provide the necessary high power to lift and maneuver large heavy loads such as containers, while battery electric counterbalanced forklifts are ideal for operating in rooms where ventilation may be an issue as they do not emit any toxic fumes.

Counterbalanced forklifts

Increase versatility with additional attachments

Counterbalanced forklifts can be equipped with a variety of attachments to add extra versatility to operations.

Attachments such as the following examples increase the versatility of a counterbalanced forklift by enabling it to perform tasks that would not normally be possible.

Clamps such as bale clamps or paper roll clamps allow counterbalanced forklifts to safely pick up and lift bales or irregularly shaped loads including bales of cotton, wool or paper rolls that cannot be picked up or lifted using a standard forklift.

Telehandler (or telescopic forklift) is a hydraulic lifting machine used to move and place heavy objects. It is sometimes also called a boom lift, and uses a crane-like tool (called a boom) to move the load. Operators attach attachments to the end of the boom to carry different materials. Attachments are designed to match the type of load they carry, such as a forklift for a pallet or a bucket for shoveling dirt.

Some operators refer to telehandlers as a combination of a forklift and a crane. Not only can they move loads around a job site, but the boom of a telehandler allows them to move with more precision and flexibility. No other piece of equipment can move thousands of pounds with such high mobility. Investing in a machine that can do multiple jobs helps teams stay within project budgets.

Uses of a telehandler

Operators rely on the flexibility of a telehandler to move different types of loads. By using different attachments, the boom can transport a variety of materials within the same workspace. Because of its precise movements, operators can lift materials over or around obstacles in tight spaces. They stay level even on uneven ground and off-road.

With their benefits, telehandlers are a cost-effective tool in the construction and agricultural sectors. Telehandler operators consider the needs of each industry when choosing attachments. In construction projects, forklifts can move pallets and raw materials over uneven terrain; in the agricultural sector, buckets can reach into hoppers and high-sided trailers.

What are the benefits of telehandlers?

Telehandlers have advantages that other equipment can’t match. They have some of the functions of forklifts and cranes, but are designed to be more flexible and versatile. Most industrial machinery works best in specific conditions. However, telehandlers play an important role in a variety of situations.

Different attachments

Depending on the industry, operators may need to move different materials in a day. Whether it’s pallets or dirt, they need different tools to move each material. This is where telehandlers come in. Since operators can change attachments between different materials, one machine can do the work of multiple equipment.

Suitable for any environment

Moving materials indoors on flat ground is simple. But for outdoor projects, workers may need to move materials over uneven ground. This is where telehandlers are essential. Because telehandlers are able to leverage their weight on all surfaces, operators can use them on any terrain without adding additional safety protocols.

Full Range of Motion

Many lifting tools have a limited range of motion. For example, a forklift can only transport materials at one height. Because a telehandler has a boom, operators can lift materials to another level or move them diagonally. This precision also allows for movement in tight spaces and around obstacles.

Choosing the right equipment for your project

Both counterbalanced forklifts and telehandlers excel in different conditions, with their strengths being best suited to the task at hand. For forklifts, this includes navigating indoors and outdoors, navigating tight spaces, and lifting cargo loads to racks or other elevated locations. Telehandlers, on the other hand, excel at picking up loads from multiple directions and transporting loads over rough outdoor terrain.

Please contact us for more expertise and consultation to get factory wholesale prices